REGENERATIVE, ORGANIC, CONSCIOUS AND FAIR

Each chocolate bar is unique, different and of great quality.

THE PROCESS OF ARTISAN CHOCOLATE

We do not use sophisticated technology, chemicals or highly industrialized ingredients. This way we guarantee that our products are good, clean and fair.

WE ENHANCE THE FLAVORS

and unique aromas of the world-famous Cacao Nacional Fino de Aroma at all stages of cocoa processing.

1: SOWING

We only plant Cacao Fino de Aroma Nacional in regenerative agriculture systems (agricultural systems that contribute to the connectivity and relationships of the ecosystem and people), seeking to grow our cocoa immersed in balanced agroforests. This guarantees us the complexity of aromas and flavors that are generated only by working with biodiversity!

2: HARVESTING COCOA AND OTHER INGREDIENTS THAT ACCOMPANY IT

We harvest the cocoa every 15 days, ensuring that the pods reach the ideal maturity for good fermentation. The other fruits and spices that accompany our chocolates (cardamom, salak, guayabilla and more) also come from the farm, where they grow in harmony with the cocoa trees.

3: POST-HARVEST

Post-harvest is one of the most delicate moments to obtain excellent chocolate, so we follow these steps:

FERMENTATION

It requires special care in controlling the environmental factors that influence the flavors and aromas of cocoa.

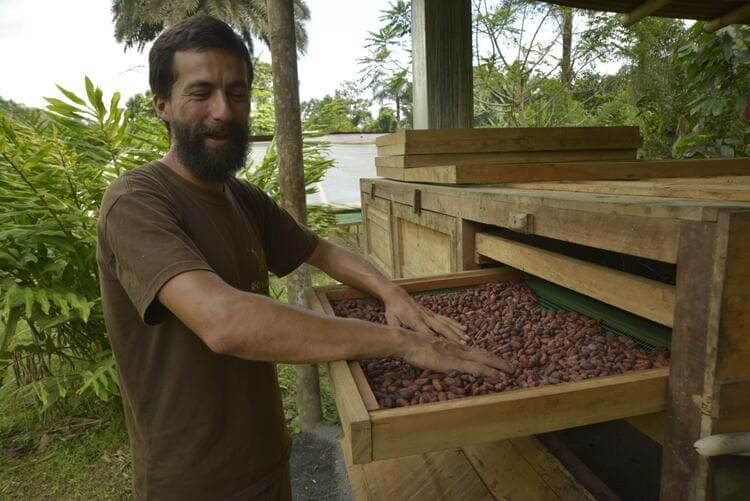

drying

Drying is carried out very slowly. At Mashpi Chocolate we achieve ideal drying thanks to an efficient “Rocket” combustion oven. This oven is an innovative technology that has allowed us to free ourselves from external energy sources such as gas or oil, and reduce our carbon emissions. All the firewood used in this oven comes from the farm’s agroforestry systems!

4: SELECT, ROAST AND PEEL

Once the cocoa beans have been selected, we roast and shell them very carefully. We do a large part of this process manually to ensure that we select the best almonds and obtain cocoa nibs without impurities.

5: REFINE, SHELL AND TEMPER

We refine it in a high-quality mill, where we precisely control the temperature and refining time to achieve the best results. We then transfer the chocolate to the conching machine, where it remains in constant motion for a few more hours and where the other ingredients that accompany our chocolate bars are mixed.

6: PACK

We package our products manually, thus ensuring quality and also jobs for the people involved in the creation of these products. Almost all of our packaging is made from eco-friendly paper derived from sugarcane bagasse.

7. WE INNOVATE

We are moving away from paper with resins, plastics and glitter that make it impossible to fully recycle the packaging. We minimise the use of plastic in our packaging and do not use aluminium bags; we reuse cardboard packaging and dispenser boxes as much as possible.